Precision Manufacturing for Small Quantities

Low Volume PCB Assembly has become an essential service for companies that require high-quality printed circuit boards in smaller quantities. This approach is ideal for product prototypes, market testing, or specialized electronics that do not demand mass production. By focusing on small batch orders, manufacturers can deliver the same level of precision and performance as high-volume production, while giving clients the flexibility to adjust designs before committing to large-scale manufacturing.

Advantages of Low Volume PCB Assembly

Choosing Low Volume PCB Assembly offers multiple benefits, especially for businesses seeking cost efficiency without sacrificing quality. Small batch production allows companies to reduce upfront expenses, minimize inventory costs, and adapt to market changes quickly. This process also enables engineers and designers to identify potential improvements before moving toward mass production, helping to optimize both performance and manufacturing efficiency.

Flexible Production to Match Diverse Needs

The flexibility offered by Low Volume PCB Assembly makes it a preferred choice for industries with varying demands. From medical equipment and aerospace technology to industrial automation and consumer electronics, small batch orders are often the most practical solution. This approach ensures that each order can be tailored to meet the specific requirements of the project, including unique board layouts, specialized components, and custom assembly techniques.

Advanced Technology for Quality Results

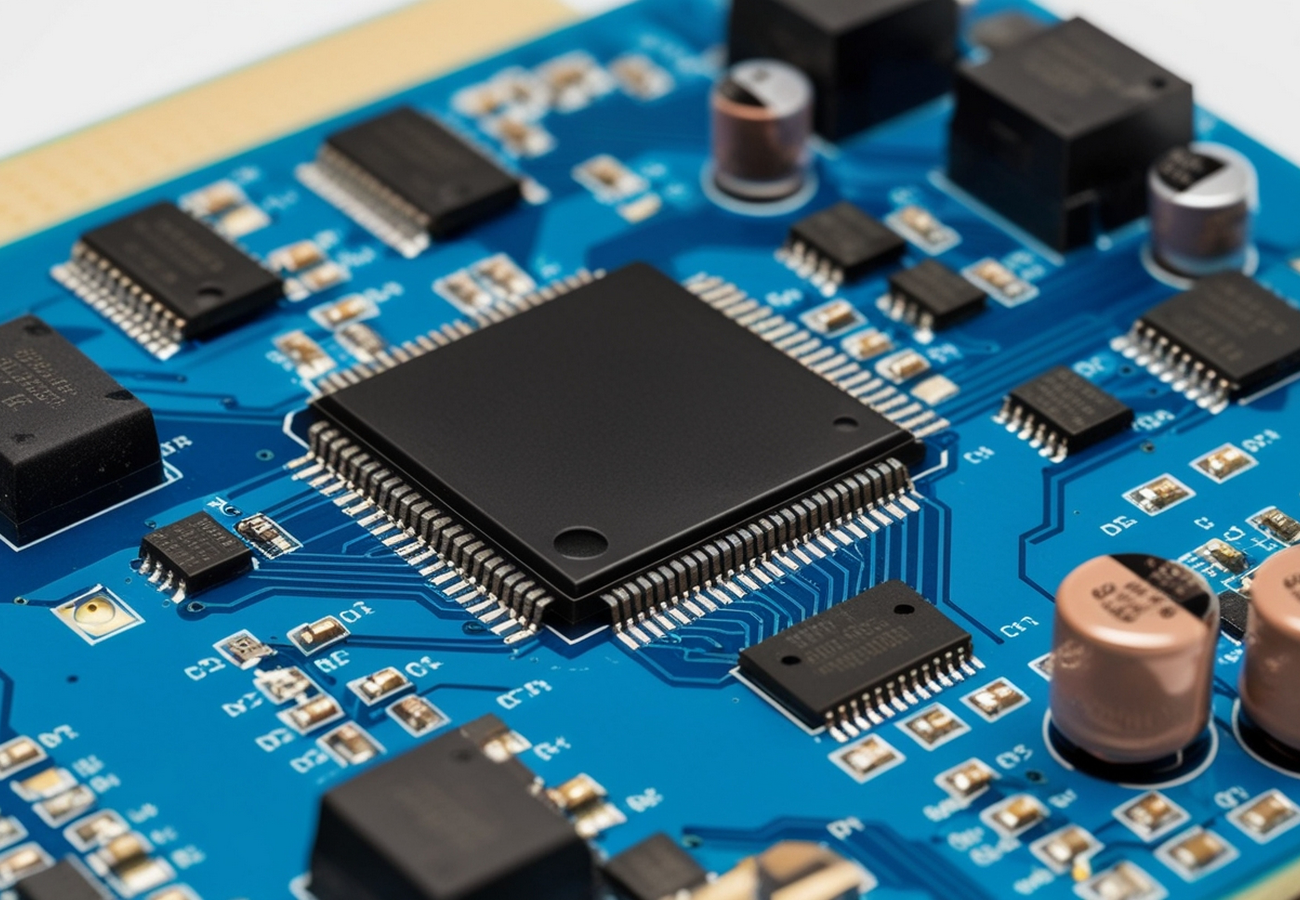

Modern manufacturing facilities specializing in Low Volume PCB Assembly use advanced production equipment to ensure accuracy and consistency. Automated pick-and-place machines, high-quality soldering processes, and thorough testing protocols guarantee that even the smallest batches meet industry standards. By combining cutting-edge technology with skilled workmanship, manufacturers can produce boards that are both reliable and cost-effective.

Cost-Effective Testing and Prototyping

One of the main reasons companies choose Low Volume PCB Assembly is to create prototypes that can be thoroughly tested before full-scale production. This reduces the risk of costly design errors and ensures that the final product meets performance expectations. Small batch assembly provides an affordable way to refine designs, evaluate different materials, and test component compatibility without committing to large production runs.

Customization and Rapid Turnaround

Low Volume PCB Assembly also allows for greater customization in design and material selection. Manufacturers can adapt quickly to client requirements, offering options for different board thicknesses, copper weights, and surface finishes. In addition, the smaller production volume enables faster turnaround times, helping companies meet tight deadlines and respond quickly to market demands.

Supporting Innovation and Startups

For startups and innovators, Low Volume PCB Assembly is a cost-effective path to bringing new ideas to life. By producing small batches, companies can introduce products to market faster, gather user feedback, and make adjustments without the financial risks associated with large-scale manufacturing. This agile approach supports continuous improvement and accelerates the product development cycle.

Meeting Industry Standards for Reliability

Even in small quantities, quality control is a top priority in Low Volume PCB Assembly. Each board is subjected to rigorous inspections and functional testing to ensure it performs as expected in real-world conditions. Whether used in critical applications like medical monitoring devices or industrial machinery, these boards are built to meet strict industry standards for safety and reliability.

The Future of Small Batch PCB Manufacturing

With the growing demand for specialized electronics and customized solutions, Low Volume PCB Assembly is set to play a larger role in the electronics industry. Its combination of flexibility, affordability, and precision makes it the ideal choice for businesses that value quality and adaptability. As technology advances, the capabilities of small batch manufacturing will continue to expand, offering even greater opportunities for innovation and product development.