Introduction to Hairise Modular Belt Systems

In the competitive world of manufacturing and logistics, efficiency and reliability are paramount. One crucial component that helps businesses achieve these goals is the Hairise modular belt system. The Hairise modular belt is engineered to provide superior performance and durability in material handling applications. With industries requiring systems that can withstand heavy use, varying load types, and long operational hours, the Hairise modular belt is designed to deliver maximum reliability under demanding conditions. The robust construction of the Hairise modular belt makes it an ideal solution for industries such as food processing, automotive, pharmaceuticals, and packaging. The modular design allows businesses to easily customize the system to meet their specific operational needs, ensuring both flexibility and efficiency. The Hairise modular belt is constructed using high-quality materials, which enhances its ability to handle challenging environments and heavy loads. These belts are also known for their low-maintenance design, which helps reduce operational downtime and ensures that systems stay up and running for extended periods. By offering high durability and exceptional performance, the Hairise modular belt is quickly becoming a preferred choice for industries around the globe. Whether it’s conveying lightweight parts or handling heavy-duty materials, the Hairise modular belt provides a seamless solution that boosts productivity and minimizes disruptions in operations.

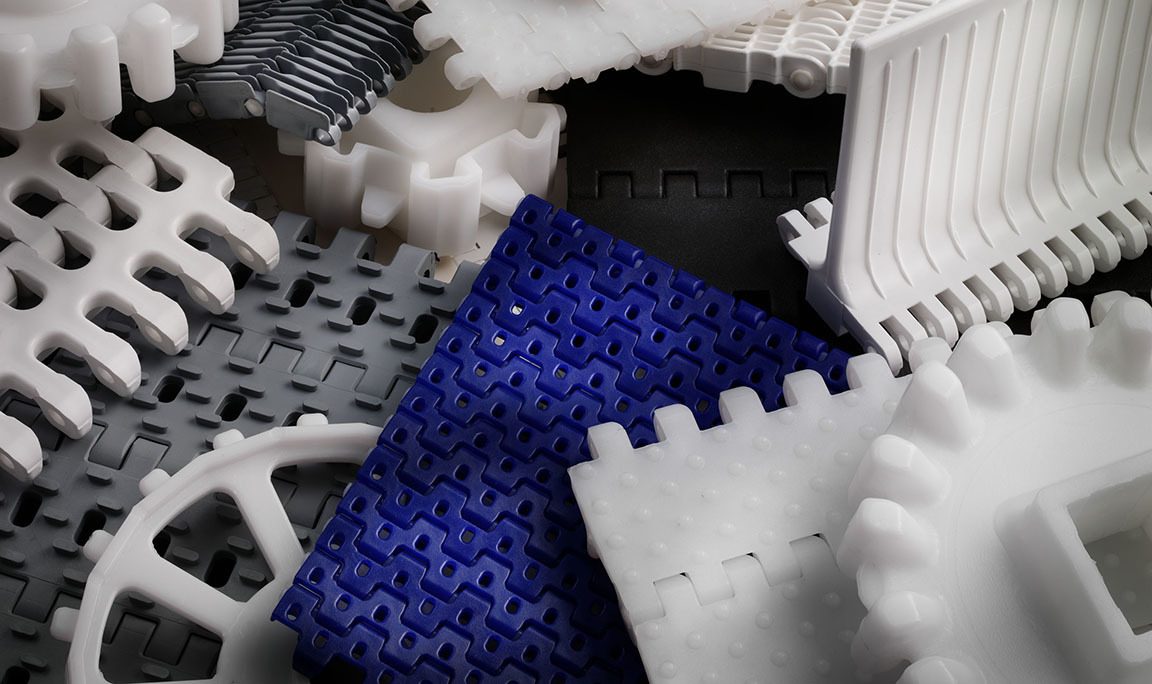

Features of the Hairise Modular Belt System

The Hairise modular belt system stands out due to its numerous advanced features, making it one of the most reliable and high-performing systems available. One of the primary features of the Hairise modular belt is its modular design, which provides unparalleled flexibility in terms of customization and maintenance. The modular nature of the belt allows businesses to easily replace or modify individual sections without needing to replace the entire system. This reduces downtime and makes maintenance far simpler, saving both time and money for operations. The Hairise modular belt also boasts robust materials and a strong build, which enables it to handle heavy loads and demanding conditions. Whether it is used in harsh environments or in industries where hygiene is a top priority, the Hairise modular belt can be designed with specialized materials to meet these challenges. For example, in food processing environments, the Hairise modular belt can be made from food-grade materials that comply with strict safety standards. This attention to detail ensures that the Hairise modular belt not only performs well but is also safe and compliant with industry regulations. Additionally, the Hairise modular belt is engineered to provide smooth, uninterrupted motion, reducing wear and tear on both the belt and the machinery. This results in a system that is both cost-effective and energy-efficient, helping businesses keep operational costs low while maintaining optimal productivity.

Durability and Reliability of the Hairise Modular Belt

One of the standout qualities of the Hairise modular belt system is its durability. Designed to withstand constant use and the harshest operational environments, the Hairise modular belt is built with high-strength materials that ensure long-term reliability. Unlike traditional conveyor systems that may require frequent repairs or replacements, the Hairise modular belt is specifically engineered to resist wear and tear, minimizing the need for maintenance. The high durability of the Hairise modular belt helps companies reduce their operational downtime, increase productivity, and ensure that their systems remain up and running without frequent interruptions. Additionally, the Hairise modular belt is designed to handle a wide range of applications, from lightweight materials to heavy-duty loads, which further boosts its versatility and durability. In industries where extreme conditions or high heat are factors, the Hairise modular belt is capable of performing at optimal levels without compromising on strength or functionality. This ability to maintain high performance over extended periods is one of the primary reasons why the Hairise modular belt system is trusted by companies in diverse sectors worldwide. The reliability of the Hairise modular belt ensures that businesses can count on their material handling systems to operate smoothly and efficiently, even under the most challenging conditions.

The High-Performance Capabilities of Hairise Modular Belt Systems

The Hairise modular belt is engineered to provide high performance in a variety of material handling applications. Its versatility allows it to excel in a wide range of industries, from packaging to automotive assembly lines. The Hairise modular belt provides smooth, efficient transportation of goods, minimizing delays and improving throughput. In addition to its ability to handle different types of materials, the Hairise modular belt is also designed to operate at high speeds, ensuring that production lines maintain a fast pace without sacrificing quality or safety. Its advanced design also enables seamless integration with other systems such as automated sorting and packaging machines. This capability ensures that the Hairise modular belt can be part of a fully automated system, helping businesses achieve a higher level of operational efficiency. The advanced technology behind the Hairise modular belt allows it to maintain consistent speed and performance, even when transporting items of varying sizes, shapes, or weights. This is especially important in industries such as automotive manufacturing, where precision and efficiency are critical. Furthermore, the Hairise modular belt system can be customized to accommodate specific operational needs, such as different belt materials, widths, or configurations. This adaptability makes the Hairise modular belt a versatile solution for businesses that need to scale operations or modify production lines to meet changing demands.

Easy Maintenance and Long-Term Savings

One of the key advantages of the Hairise modular belt system is its ease of maintenance. Unlike traditional conveyor belts, which may require extensive repairs or replacements, the Hairise modular belt is designed for minimal upkeep. Its modular design allows businesses to replace only the individual segments that are worn or damaged, rather than the entire belt system. This reduces both maintenance costs and downtime, allowing businesses to keep their operations running smoothly and efficiently. The design of the Hairise modular belt also minimizes wear on the belt and associated components, extending the life of the system and reducing the frequency of replacements. For industries with high-volume production, this extended lifespan translates to significant long-term savings. Moreover, the low-maintenance nature of the Hairise modular belt system reduces the need for specialized labor and costly repair services, providing additional cost savings for businesses. The ability to maintain high performance with minimal effort makes the Hairise modular belt a smart investment for companies seeking to optimize their material handling processes and improve their bottom line. This focus on durability and easy maintenance ensures that the Hairise modular belt provides both short-term efficiency and long-term value.

Applications of the Hairise Modular Belt in Various Industries

The Hairise modular belt system is used across a wide array of industries, demonstrating its versatility and reliability. In the food processing industry, the Hairise modular belt is ideal for handling food products while maintaining hygiene standards and reducing contamination risks. The ability to clean and sanitize the Hairise modular belt easily makes it an essential part of modern food production lines. In the automotive industry, the Hairise modular belt is used to transport parts and finished vehicles along assembly lines. Its high strength and durability make it suitable for handling heavy automotive components. In pharmaceutical manufacturing, the Hairise modular belt ensures safe and efficient transport of delicate products, meeting strict industry regulations. Similarly, the Hairise modular belt is widely used in electronics manufacturing, where its smooth operation and high precision are critical for assembling sensitive components. Additionally, the Hairise modular belt is used in the packaging industry, where it helps efficiently move products through packaging lines. Its flexibility allows it to be customized for various tasks, making it an invaluable asset in numerous sectors.

Conclusion

The Hairise modular belt is a high-performance, durable, and reliable solution for material handling needs. Engineered to withstand demanding conditions and provide consistent performance, the Hairise modular belt is the ideal choice for businesses looking to optimize their operations. With its modular design, ease of maintenance, and adaptability, the Hairise modular belt ensures long-term reliability and operational efficiency. Whether for use in food processing, automotive assembly, pharmaceuticals, or packaging, the Hairise modular belt is built to meet the challenges of modern industries, delivering performance, durability, and value. Investing in a Hairise modular belt system ensures that businesses can maintain smooth and efficient operations while reducing downtime and long-term maintenance costs.